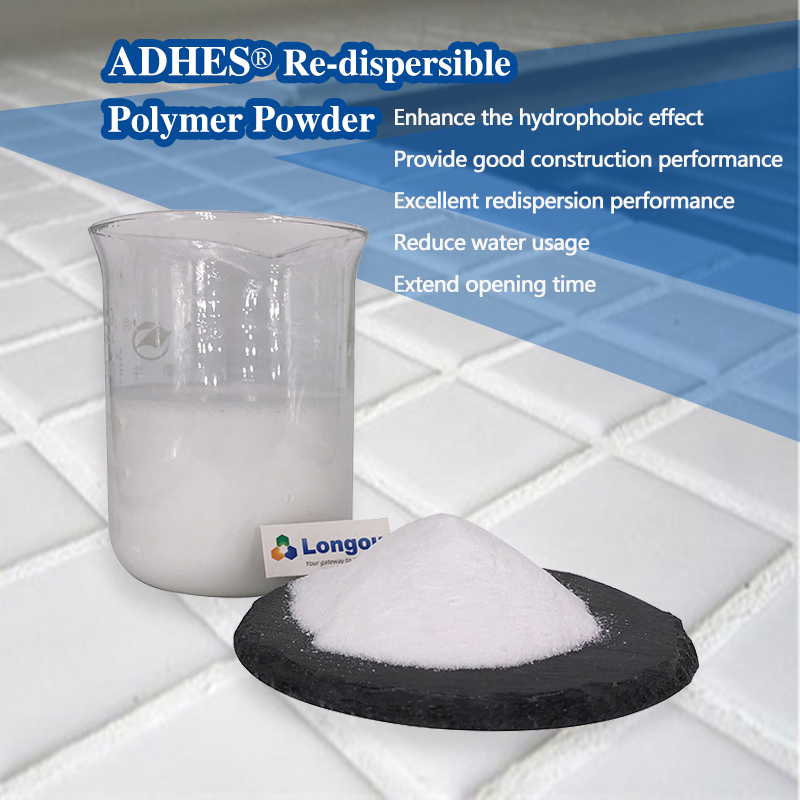

Redispersible polymer powder has a wide range of applications. It is playing an active role in wider and wider applications. Like ceramic tile adhesive, wall putty and insulation mortar for exterior walls, all have close relations to redispersible polymer powder.

The addition ofredispersible latex powder can increase the compactness of the mortar and enhance its industrial indicators including tensile strength, bending strength, etc. Compared with the building withoutRDP, the overall quality and strength have been significantly improved.

Let’s see the roles of redispersible polymer powder in different mortars.

Adhesive mortar: Ensure that the mortar will firmly bond the wall to the EPS board. Improve bond strength.

Plastering mortar: Ensure the mechanical strength of the insulation system, crack resistance and durability, and impact resistance.

Tile grout: Give the mortar excellent impermeability and prevent water intrusion. At the same time, it has good adhesion, low shrinkage and flexibility to the edge of the tile.

Wall puttyfor interior and exterior walls: improve the bonding strength of putty and ensure that the putty has a certain flexibility to buffer the different expansion and contraction stresses produced by different base layers. Ensure that the putty has good aging resistance, impermeability and moisture resistance.

Ceramic tile renovation and plastering putty: improve the adhesion and bonding strength of putty on special substrates (such as tile surface, mosaic, plywood and other smooth surfaces), and ensure that the putty has good flexibility to strain the expansion coefficient of the substrate.

Masonry plastering mortar: Improves water retention. Reduces water loss to porous substrates.

Cement-based waterproof mortar: Ensure the waterproof performance of the mortar coating, and at the same time have good adhesion to the base surface, and improve the compressive and flexural strength of the mortar.

Self-leveling floor mortar: Ensure the matching of the elastic modulus, bending resistance and crack resistance of the mortar. Improve the wear resistance, bonding strength and cohesion of mortar.

Interface mortar: improve the surface strength of the substrate and ensure the adhesion of the mortar.

Repair mortar: Ensure that the expansion coefficient of the mortar matches the base material, and reduce the elastic modulus of the mortar. Make sure the mortar has sufficient water repellency, air permeability and cohesive force.

Tile Adhesive: Provides a high-strength bond to the mortar, giving the mortar enough flexibility to accommodate the different coefficients of thermal expansion of the substrate and tiles. Improve the ease of construction operation and improve work efficiency.

Post time: Aug-03-2023